How to drill a vertical top hole

Top hole drilling is as much science as art. But in order to do it right, you’ve got to mean business. Here are three basic things you need to get right in order to avoid building inclination. Follow these principles and you will end up with a vertical top hole, and not the Leaning Tower of Pisa.

For a top hole to be defined as vertical, you must in most cases not exceed one degree. There are several reasons why we want the hole to be vertical. One obvious scenario is template drilling, where you often have four to six wells very close to each other. But in general, vertical wells are more friendly and less likely to give you problems when you want to land the wellhead, the marine riser and the BOP.

1. Pick the right weapon

The leading actor in the drill string, is the hole opener. These heavy guys come in all shapes and sizes, so make sure you pick one that is up to the job. (They’re supposed to bust boulders, you know).

Pay special attention and consideration to the cutter type. There are basically to types: TCI cutters (Tungsten Carbide Insert) and mill tooth cutters. Here are some points to consider regarding cutters:

- In areas with boulders, milled tooth cutters are more prone to locking up due to picking up floating pebbles in the formation which can jam the cutters

- Milled tooth cutters are much more prone to tooth wear when run in abrasive formations.

- TCI cutters have stronger and smaller teeth and deliver higher ROP in hard formations, with less wear than their milled tooth counterparts

Picking the wrong cutter can be expensive and will reduce cutter effectivity significantly. You should therefore discuss the choice of cutters carefully with your provider.

If in doubt, go for TCI cutters (Tungsten Carbide Insert). Especially if you expect boulders and pebbles down there. Mill tooth cutters have big teeth where rocks and gravel tends to get stuck. When these teeth get worn down, it will take you many extra hours getting through the last few meters down to TD (Total Depth).

>Read also: Hole openers: When your black gold is between a rock and a hard place

2. Go big or go home

Get the biggest possible BHA equipment (Bottom Hole Assembly). The heavier the hole opener, the better. As for the other components, we’re talking 9,5″ drill collars. A heavier BHA is rigid and makes it easier to stay vertical.

3. Don’t push it!

Don’t push the tool. Let the force of gravity do what it’s best at – namely pulling stuff downwards. So let the weight of the hole opener lead, do not apply too much weight, but rather pull in the reins. If the hole angle deviates from vertical >1 degree just below the template, attempt to straighten the hole by reaming.

If you put too much weight on the bit (WOB), the hole opener will cause the neutral point to move up. If the neutral point is moved too high above the seafloor, there is an increased risk for twist-off (the string breaks). Especially in deep waters. As a rule of thumb your WOB should not exeed the weight of your BHA.

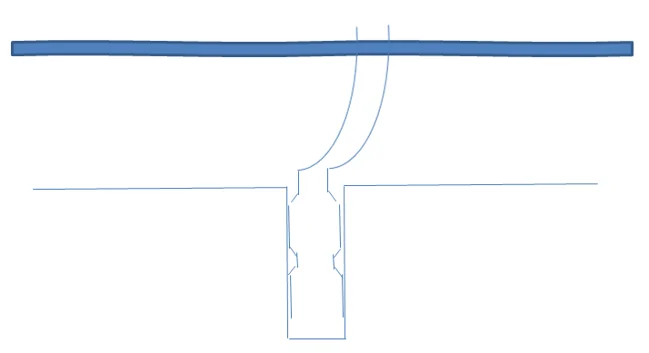

The illustration above shows what might happen if you put too much weight on the bit. The thick blue line is the sea surface and the thin line is the sea floor. Here we see that the drill string has started to buckle above the sea floor, while the BHA and hole opener is in the hole.

Be aware that the MWD (Measurement while Drilling) instrument (sitting close to the bit, in the hole) might not necessarily indicate that buckling is going on, so you will get no forewarning, other than what your experience based knowledge will tell you.

> Read also: What is drill pipe buckling and how to prevent it from happening

BONUS: Recipe for success top holes

Vertical top hole drilling in one sentence:

As your drill bit approaches the seafloor, start the pumps and spud in 5-10 meters. Gradually increase flow and rotation as the formation gets more solid.

Description of a normal procedure

- Wash down first 2-5 meters 500-1 000 LPM (Liters Per Minute) before string rotation is started

- Next 5-10 meters: 30-50 RPM / 1 000-1 500 LPM

- Continue to increase the string rotation in steps up to 80-100 RPM (Revolutions Per Minute)

- Increase flow stepwise up to 4 000 LPM

- Sufficient ROP (Rate of Penetration) will be achieved with a WOB (Weight of Bit) of 3-7 tons

Drilling jars and energizers

In rough drilling operations it may be practical to use a 9 ½” drilling jar & energizer as an extra safety factor to avoid getting stuck during drilling. A Jar will help you if you get mechanically stuck due to boulders falling in. An accelerator would smoothen out the bouncing through the string up to the derrick. An accelerator will also increase the impact on the jar in lack of pipe stretch, especially in shallow wells.

Total Flow Area (TFA)

One last thing … consider how you plan to distribute the flow rate between the bit and the hole opener. We recommend a 60/40 ratio, because the hole opener (36″) opens up a much bigger area than the bit (17,5″).

Topics: Drilling

By: Tor Helge Hestetun & Trond Inge Mitchell

Tor Helge and Trond Inge work as Sales & Project Engineers at Odfjell Well Services in Stavanger, and worked together on the ENI Boulder Buster project.