Tripping out or cashing in?

Different methods and technology for reducing the number of well trips have been around for some years; however, as a result of the latest market down-cycle period, these approaches have gained fresh interest, creating a new wave of development in technology-based solutions. In this article I will go into further detail about three of Odfjell Well Services’ main technologies on how to reduce tripping.

How much time is spent in the planning stages asking the question: “can this trip be avoided”?At Odfjell Well Services we offer a range of diverse services, and our product lines are reinforced with complimentary products and technologies aimed at just that – to reduce tripping and save costs.

New products and technical achievements have met a market craving for efficiency gains. Where we struggled even to get to talk about these tools and methods a few years ago, we now see a different attitude from both operators and oil companies.

Three of our main technologies and services are fundamental in creating these results, all of them aiming at and contributing towards eliminating trips.

1. Casing while Drilling

Combining two operations in one, the Casing While Drilling (CwD) technology has been developed beyond its traditional limits and to new levels recently; enabling the process to now be used in long, horizontal sections. The CwD-method, formerly limited in the most part, to top sections, and in places like Romania, is now being successfully run in challenging wells in many other parts of the world.

Enhanced Casing Installation (ECI) is a Retrievable Casing while Drilling (RCwD) system. The system is designed with a directional drilling assembly securely locked onto the casing string, which can then be used to drill and case the section simultaneously. Upon completion of the section, the drilling assembly is disengaged and retrieved back to surface. Furthermore, gamma and resistivity tools are positioned behind aluminium and composite casing enabling the use of MWD and LWD logging from inside the casing, while drilling without magnetic interference.

2. Defuse High-Speed Reamer

It’s not just the planned trips for unconventional drilling solutions that we are striving to avoid. Just as important is how to avoid the unwanted, unscheduled trips in response to unforeseen problems. When you run the casing from the top drive using a Casing Running Tool (CRT), a technology widely utilized now in many global operations your options to manoeuvre the casing are, if not limitless, very near to it. Add to this versatility a high-speed, hydraulically activated reamer that rotates freely, passing over ledges in the wellbore without the aid of the pump, and you have an unstoppable combination.

Typically, the Defuse high-speed reamer will be included when running casing through problematic formations, and can overcome micro doglegs caused by directional drilling tools, resulting in a nominal drift ID hole. Having a powerful, hydraulically activated drive system at the end of the casing string is a valuable addition to the toolbox especially when compared to the time consuming and counterproductive task of pulling the casing, washing out the wellbore and running the casing back in the hole.

3. Combining drilling and lower completion

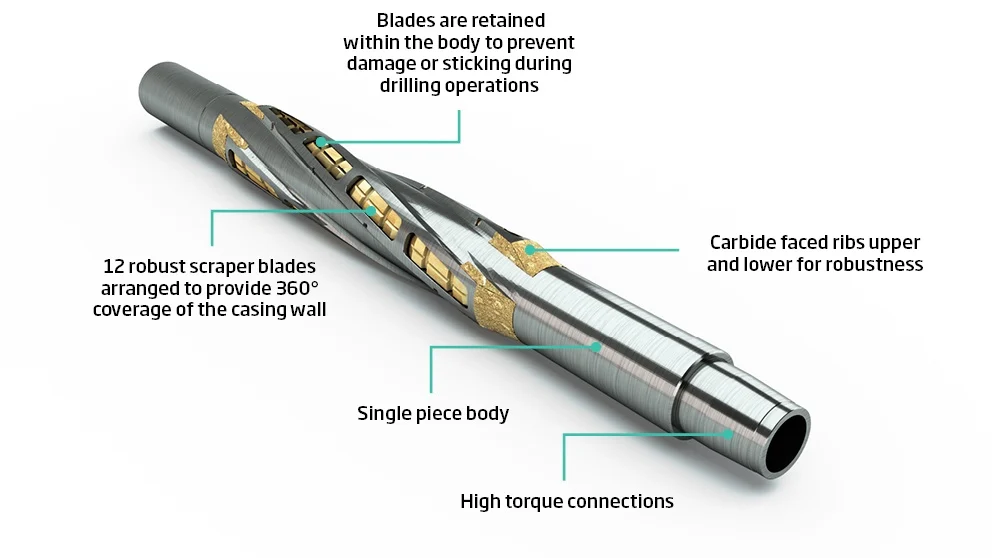

A fully dedicated WBCU run with a comprehensive BHA (bottom-hole assembly) is an operation lasting 24 or more hours. Eliminating this trip will instantly reduce the well delivery cost. Until recently, the benefit of combining drilling and lower completion was all but evident but now with the OWS DrillRdillo™, we have a tool that handles high-torque situations in drilling while functioning as a conventional casing scraper. The DrillRdillo™ Dynamic Casing Scraper delivers time and cost savings across drilling, completion, remedial and decommissioning operations by empowering the client with further options to optimize their operations, eliminating the need for a dedicated WBCU run.

Read more: The DrillRdillo casing scraper: The story so far [Infographic]

With full 360° coverage, the DrillRdillo™ Drilling Scraper (DRD) scraper blades are safely retained during drilling or pre-completion operations. When the time comes to activate the tool, drop a ball and pressure up to release the scraper blades; then, either string rotation or reciprocation can be used to scrape the casing wall whilst pulling out of the well.

Drilling: Run in the Drilling BHA, the DrillRdillo™ scrapes/cleans the casing packer setting depths before tripping out of the hole.

Completion: Run as an integral part of the Liner Setting assembly. Scrapes/cleans the casing packer setting depth before tripping out.

Remedial: Run in conjunction with the milling assembly. Multiple DrillRdillos™ can be run in a single BHA to scrape/mill multiple casings sizes.

Decommissioning: Scrapes Liners/Casing prior to Logging for assessment of TOC and Liner/casing condition. The tool runs in the drill string in a switched-off mode when drilling open sections. The blades are activated by a ball drop to scrape the lower completion packer and hanger areas.

Since its launch, the DrillRdillo™ has demonstrated its unique design and robustness in various applications, resulting in valuable rig time being saved for our clients globally.

Get the real work done

When running tubulars into the well, sealing off the section correctly and on time is your primary aim. However, we all spend hours, days, and weeks in the drilling cabin or on the drill floor not casing the well and leaving the formation exposed to drilling and mud, instead of getting the real work done.

Besides being utterly dull and exposing personnel to hours of hazardous and repetitive tasks, tripping in and out is a constant drain on profits and contributes to a significant impact on the total cost of the well. Like ripples in the water, the expenses add up – from occupying the TRS crew, drilling crew, the mud engineers, crane operators, personnel on pipe deck and more; these expenses grow over time, and the longer activities take, the greater the overall impact.

Perfect timing

The down-cycle market has created a thriving environment for these innovations and technology improvements. The demand has been created by the imperative for our clients to deliver wells at considerably lower costs than during the heydays of our industry.

Saving trips is the most effective way to reduce these costs; removing hours and days from your operation increase your margins in an instant.

Topics: Casing Running, Casing Preparation, TRS

By: Alexandru Gomoescu

Alexandru has been in the oil and gas industry for ten years providing drilling related services such as casing drilling, tubular running and drilling equipment rental. He is now Regional Manager (CESEE) at Odfjell Well Services.