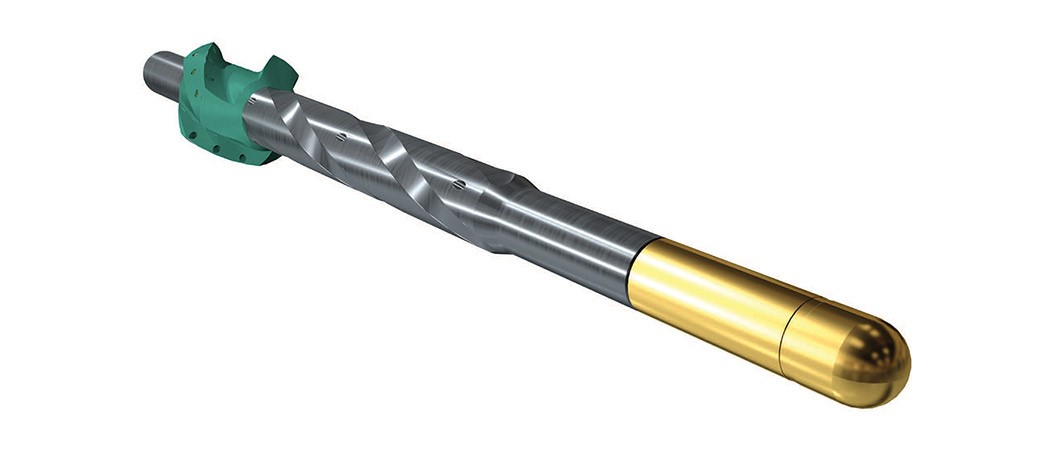

The Hydraflow™ Advanced Wellbore Cleaning System (HAWCS) utilizes a high flow rate combined with lower pump pressure to optimize Riser & BOP cleaning efficiency.

Features

- The 16” OD High-Flow Sleeve features 12 offset large TFA ports designed to clean the riser wall and effectively penetrate the BOP cavities to clear and flush out debris.

- Nine upward-angled large TFA ports are arranged along the body to help reintroduce debris into the flow path, allowing it to be carried upward to the surface.

- An optional integral pup joint is available for easier handling

- An optional Lower Bull Nose or Pin Down connection to accommodate various applications.

Benefits

- Cost Savings

- Maximizing Riser & BOP cleaning efficiency to reduce operating time has a huge impact on operating costs on expensive semi-submersibles

- No field maintenance required

- Integrity

- Available with high torque connections minimizing the need for reduced strength crossovers

- Single piece mandrel with no internal connections for increased strength

- Reducing Non-Productive Time

- Reduces premature failure of completion equipment by debris which can interfere or damage valves, electronics and other hardware

Applications

- Deep water pre-completion wellbore clean-ups from semi-submersible drilling units

- Riser cleaning during displacement to sea water before disconnection or moving from location

Operational

- The Hydraflow™ Advanced Wellbore Cleaning System (HAWCS) is typically run in conjunction with the Riser Cleaning Tool and XTractR™ BOP Junk Catcher or as a standalone tool.

- The 16” OD High-Flow Sleeve features 12 offset large TFA ports designed to clean the riser wall and effectively penetrate the BOP cavities to clear and flush out debris.

- Best practice recommends to function the rams and

- annular to help dislodge debris before jetting the BOP

- stack at 35 BPM while rotating slowly, making 3 passes.

- The upward angled nozzles assist in carrying debris to surface through inducement of turbulent flow.

- HAWCS can also be run with a wear bushing retrieval tool below.

- The high-flow sleeve is available in various sizes, 16” OD or 12.750” OD.