Casing Hanger Make Up with CRT

I have previously written about Top Drive Casing Running and the benefits of this method. However, it has a couple of downsides. I will touch upon one of the biggest challenges and what we are doing to overcome it.

What’s the problem?

As you make up and run your casing string in the hole, you will eventually get to the casing hanger. As most casing running tools apply torque from the top drive, the rotation will release the running tool from the hanger instead of making up the hanger to the rest of the casing string. The tools will also have problems engaging the pipe on top of the running tool because they either engage inside the casing or outside the casing. Either way, the jaws or dies will often be incompatible.

Use a belt tong then!

With the documentation requirements that comes with a premium connection, a belt tong or a rig tong is generally not a good solution. Why would you put a lot of effort into making sure you have a good connection and documenting it, running hundreds of casing joints with state of the art monitoring and recording equipment, and then cheat on the last and most important connection?

So what’s the solution?

In order to make up a connection from the top drive, the components below need to be rigid and unable to rotate. At least temporarily. So if you can somehow make sure that there is no rotation between the casing hanger and the casing hanger running tool, you can safely make up the hanger to the rest of the casing string. There are some differences with regards to subsea vs surface/land wells, but the principle is the same.

Is anyone doing anything about it?

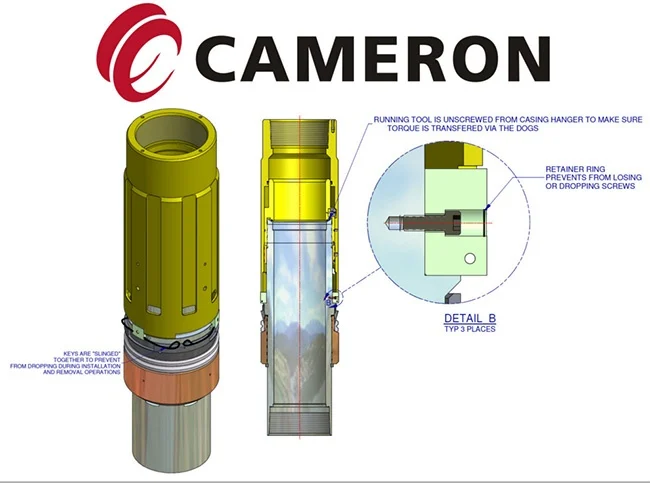

Yes! Cameron has as the only supplier developed a solution for this. As you can see below, it is a very simple but smart solution that uses locking dogs that are held in place using set screws. The assembly is pre-made onshore and the locking dogs are removed after making up the casing hanger and running tool to the rest of the string. As soon as they are removed, the tools function just as a regular running tool and the hanger are set by rotation.

Why isn’t this done on all casing hangers/running tools?

Despite all the cutting edge technology and developments, the oil & gas industry is a very conservative business. Some technologies take years (decades?) to mature and make it`s way to the oilfields. Although small, the cost associated to modifying or changing equipment may also be acting against these changes.

> Readalso: Top Drive Casing Running – why would you look for anything else?

Topics: Casing Running

By: Cato Gjesdal

Cato Gjesdal has 10 years’ experience from the oil & gas industry. As Sales & Project Engineer in Odfjell Well Services, he works with clients optimizing and improving tubular running operation such as casing running, P&A, completions and well testing.