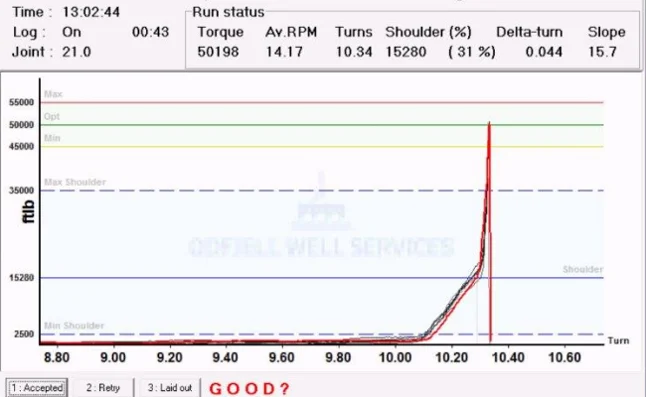

Correct interpretation of tubing/casing make up graphs

The sophisticated software developed to read make up graphs on connections of various types of casing is very helpful when making up your connections. However, don’t ever get the impression that they can replace the experienced TRS operator. The human factor is vital in understanding what the graph is reporting, and deciding if the correct torque values are within the acceptance criteria.

Calibrated equipment

One size doesn’t fit all when it comes to power tongs. This might seem like slamming in open doors, but reality is that mismatching of tongs can occur. Be careful in selecting a tong that provides the torque, speed and range suitable for the dimension of the tubulars to be made up. Failure to do this will distort the perceived picture and set you off considerably when making up.

A matching tong needs to have a correctly calibrated gauge together with compression or tension cells, and be able to provide a minimum of pulses per turn. This must be set to operate within the actual range and to recommended standards.

Talked to your software lately?

The criteria provided by the manufacturer of the tubular in question must be programmed into the computer. They are usually, but not limited to, these parameters:

- Minimum/maximum/optimum torque

- Casing size and weight (lb/ft)

- Shoulder torque

- Delta turn shoulder slope

The beauty of a tough challenge

When the snowstorm is howling, and it is -10°C, and the waves make the rig sway from side to side, making tight connections is a tough task. But it is also a situation that puts your skills as a casing operator through the ultimate test. Are you capable of applying the correct speed at the correct time when the swaying of the derrick gives you just a small time frame to run? Do you understand that the reason why your computer returns with a waving and strange graph is because the threads are getting squeezed and cross threaded from the bending of the tubular? Will you relate a graph that says “bad” to galling of the treads due to low temperature and hardening of the thread compound? Every oil field in the world has its unique set of challenges, whether it is in the burning dessert heat, in the hurricane exposed areas of the Mexico-Gulf or the cold environment of the Barents Sea. These variables cannot be programmed into your computer.

Man over machine

My point is that no equipment, no matter the level of sophistication, is capable of matching the fingerspitzgefühl and the sound judgement of a skilled casing operator with years of experience. The intelligent software is a major support in making up correctly, but the factors you need to consider to make the right decision, vary greatly. Some of them are predictable, like manufacturers specs and tubular dimensions; some are unpredictable, like weather conditions and wellbore behaviour.

So when the computer returns “unapproved” for your connection, it is not necessarily imperative to replace the tubular. During the make up, a TRS expert should be able to detect the reason for the rejection, and if a damaged connection can be repaired on site, thus saving money for the client.

Stay focused

Seeing the big picture while focusing on every single connection is the key to interpreting make up graphs correctly. A wide understanding of the different factors involved, and good communication with the driller, ensures safe and effective execution. To further highlight the importance of the human factor, I would like to stress the handover between shifts. After hours on the drill floor your knowledge of the conditions are up to date and must be treated as vital information. Make sure this is passed on to your colleagues thoroughly, giving them a head start in conquering the different challenges lurking on the drill floor and deep down in the ground.

>See also: Casing make up torque and turn

>See also: Why improved casing running requires an experienced casing crew.

Topics: Casing Running

By: Svein Krosli

Svein has been with OWS for 15 years as TRS technician, technical supervisor and instructor. He is now Global Product Line Manager, Tubular Running Services.