How to calculate the capacity of a Fill-up & Circulation Tool?

What do you need to consider when calculating the capacity of the Fill-up and circulation tool? I’ve provided you with this real life example as a reference.

>Read also: Getting the most out of Fill-Up and Circulation Tools

Calculate the expected total string weight

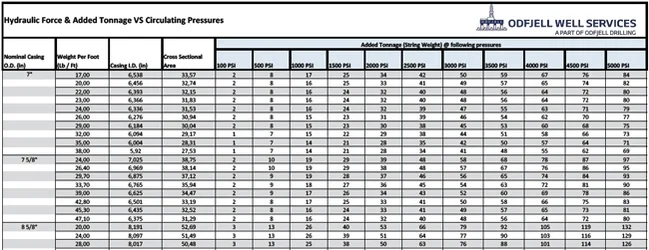

If you look at the table below (Fig 1), you will find added string weight due to the upward hydraulic force caused by circulating pressures.

For instance, if we do a simple calculation on expected string weight (in air, no buoyancy factor applied), we can easily determine our operating envelope.

Casing to be run: 9 5/8”, 53.5 PPF (pounds per foot) Vam Top, L80 Casing, 3,500 Mtr TD.

53.5 PPF = 79.62 Kg / Mtr

79.62 x 3,500 = 278,670.00 Kg

Therefore, we have an expected total string weight of 278,67 Ton (in air).

Precautions

Should we use a 350t Spider Elevator (which leaves us 71.33t margin), we could pump maximum 2000 PSI. We would add 57t of string weight onto the elevator due to the upward hydraulic force (pumping against the sealing element, forcing the fill and circulating tool up). This causes the bails and elevator to transfer more stress onto the casing, thus setting the dies of the elevator slips deeper.

Should you encounter the scenario where you have to circulate for long period of times, be sure to release/set the elevator slips regularly making sure you don’t get stuck on the casing.

Also the Mud Saver valve should be removed in case excessive hours of circulating. This prevents the valves to be washed out.

Fig.1 (click on image for full size version of the table)

Topics: Casing Running

By: Robert Koendering

Robert has 15 years experience in tubular running services which comprises pile driving, running casing & high chrome completions, bucking & pressure testing. He is an expert on top drive casing running tools & DwC operations (Level 2).