Odfjell Technology completes wellbore cleanup operation for Petronas in Indonesia

Odfjell Technology has completed a wellbore cleanup (WBCU) operation in Indonesia after successfully deploying one of its pioneering technologies and setting a new precedent for future WBCU designs.

The project for Petronas involved an extended reach drilling (ERD) well in offshore East Java and represented the first time Odfjell Technology had run its DrillRdillo Dormant Casing Scraper (DRD) in Indonesia.

As a result, significant time and cost savings were made while the need for a dedicated WBCU trip for the operation was eliminated. Rig time was reduced by 18 hours and the efficiencies achieved were valued at more than 250,000 USD through using the DRD, supported by a strongly coordinated including a dedicated on-site engineer.

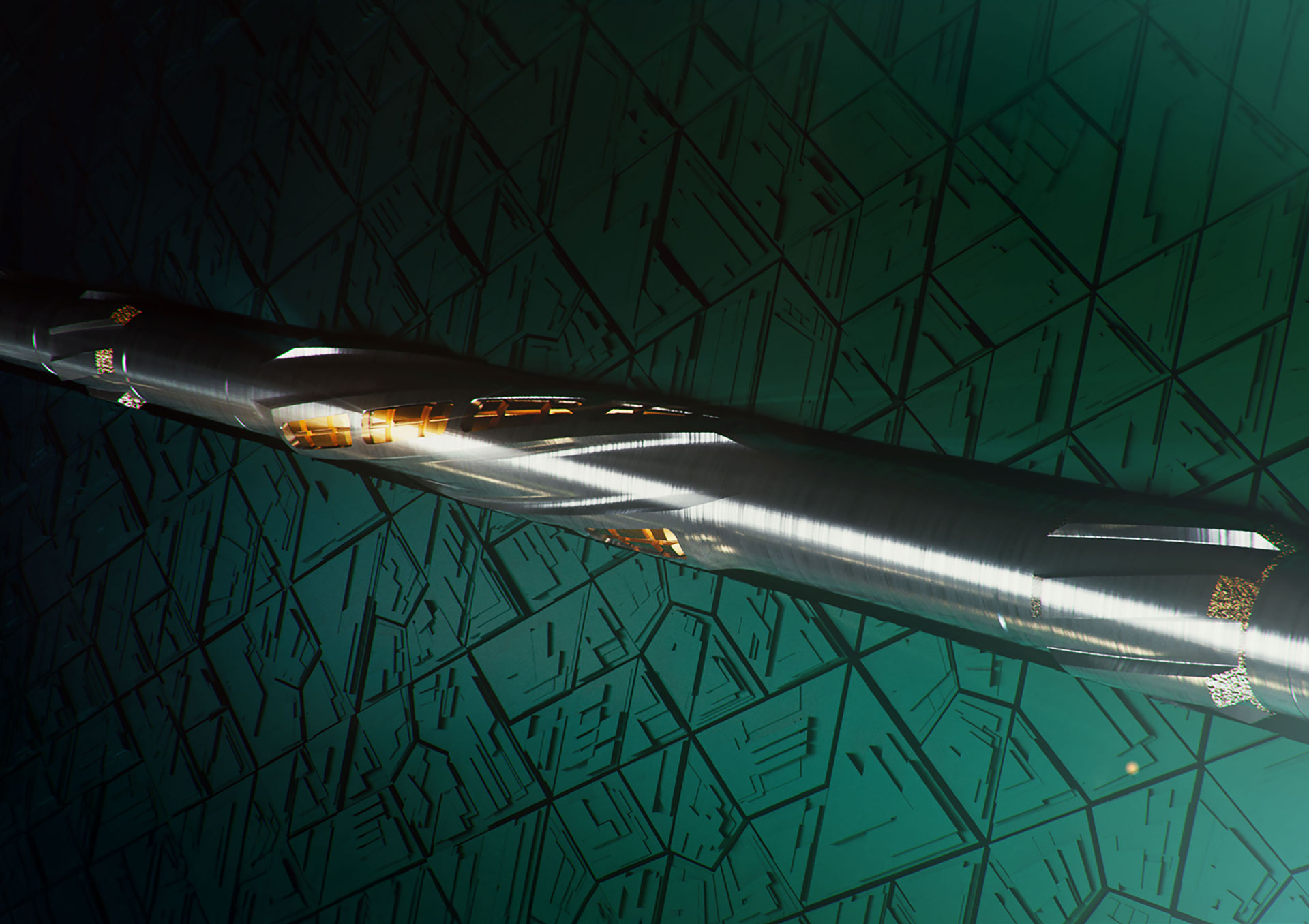

The DRD is a 360-degree contact robust scraper tool with retracted blades activated through ball drop and is designed to be run in a drilling string in dormant mode before being put to work within the casing.

It can be run in tandem with the drilling bottom hole assembly with the ability to place the scraper in the open hole and has been proven to be open hole tolerate as well as able to handle long hours of drilling.

Key benefits of the DRD tool, which has been used in more than 200 projects globally, are that it not only reduces rig time and lower costs, but it increases well productivity and maintains wellbore integrity.

Deployment of the DRD casing scraper on the ERD well – located around 35km north of the coast of Madura Island – involved a combination of workshop, field and office coordination from Malaysia and Indonesia.

Establishing good base support in delivering the equipment to Odfjell Technology’s facility in Jakarta and getting the equipment ready for the project was also crucial to the operation. This included strong coordination with Odfjell Technology’s logistics partner.

The offshore well features an 8-½” open hole over a 3,228 ft section with a near-horizontal trajectory. Using an 8.5-inch PDC bit, the drill-out was successfully completed in just 108 hours, showing the DRD can endure more than 100 hours of 8.5” drilling time.

Find out more about Odfjell Technology’s WBCU solutions here.