The difference between standard and high torque connections

As oil companies started to drill deeper, faster and in more demanding environments, the need for enhanced torsional strength arose. Engineers started to develop the standard API rotary shouldered connections (RSC) that have evolved into the kind we today know as double shouldered or high torque connections.

Another shoulder to lean on

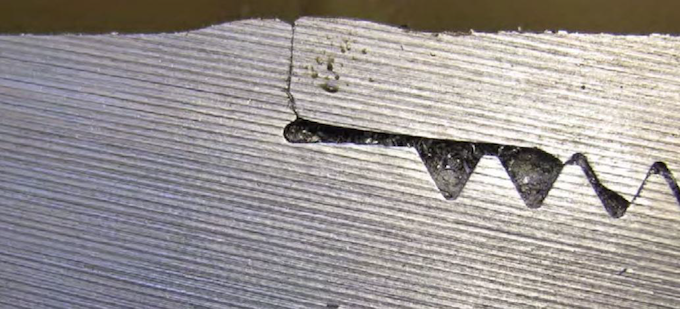

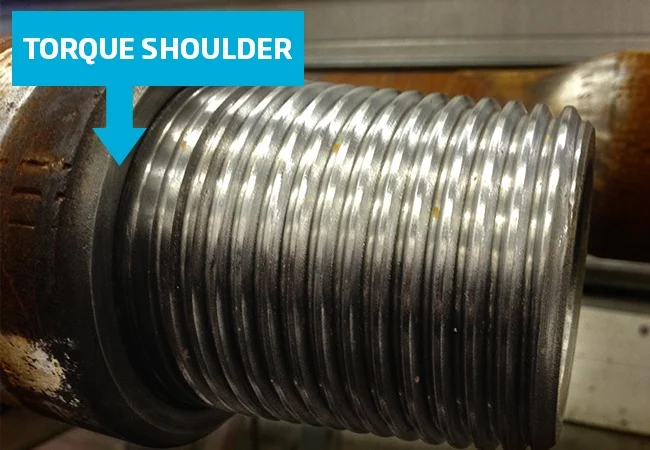

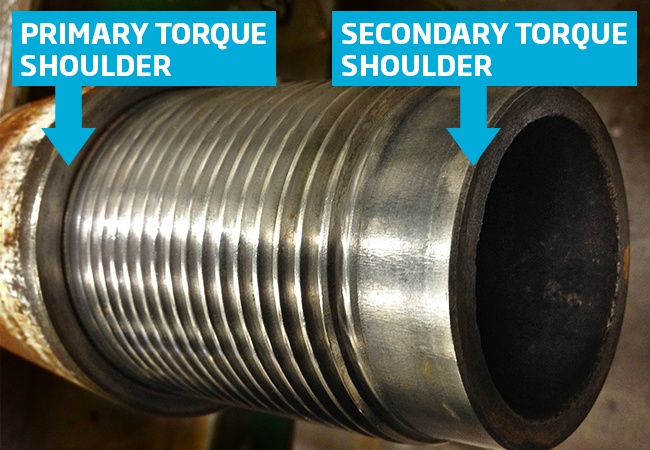

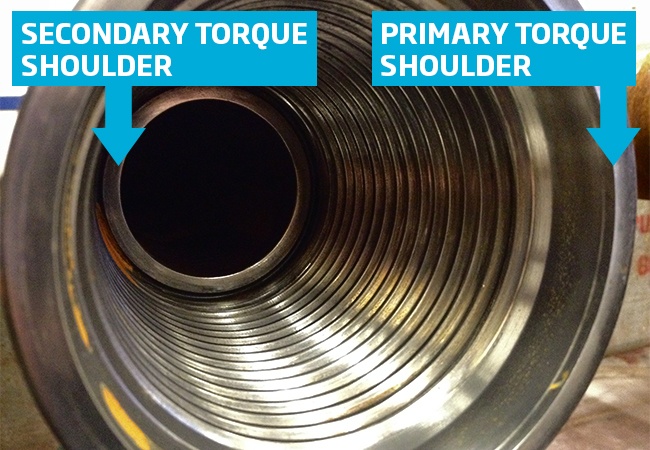

While standard API rotary shouldered connections had only one torque shoulder (see photos below), 2nd-generation rotary shouldered connections have two; a primary and a secondary torque shoulder, which gives two obvious benefits:

- Enhanced load distribution across the threaded region

- Increased torsional capacity compared to standard API rotary-shouldered connections (RSC)

Single shoulder:

> Read also: How to choose the right drill pipe

Extra power for aggressive drilling programs

The additional torsional capacity can give the driller extra required torque strength for drilling to extended depths or in more performance-demanding environments.

Double shoulder tool joints can often support larger ID’s than single shoulder assemblies. Your capacity to pump drilling mud through the pipe is bigger (improved hydraulic efficiency). Double shouldered connections can also improve wear tolerances, compared to their single shoulder counterparts.

Performance calculations

Calculations of performance for single and double shouldered connections, are done slightly different. As a rule of thumb, MUT (make up torque) is approximately 60% of maximum torsion capacity. Some pipe suppliers accept that you can increase the MUT if required, but you should never exceed 70% of the connections torsional capacity!

When people ask me if they can increase the MUT compare to what’s specified on our equipment spec-sheets, the answer can sometimes be yes, but please note: Increased MUT can, among other things, result in reduction of tension capacity!

Torque shoulders will also function as a seal shoulder, although API RSC is not pressure rated. Some double-shouldered connections are compatible with API single shouldered connections and can be made-up together. In case you choose such a solution, you must be careful and take some precautions, and at least use the make-up data for the “weakest” connection.

By: Frode Bjørheim

Frode Bjørheim is a specialist in drill pipe standards and lifting equipments with more than 30 years’ experience in the oil & gas industry, both offshore and onshore.