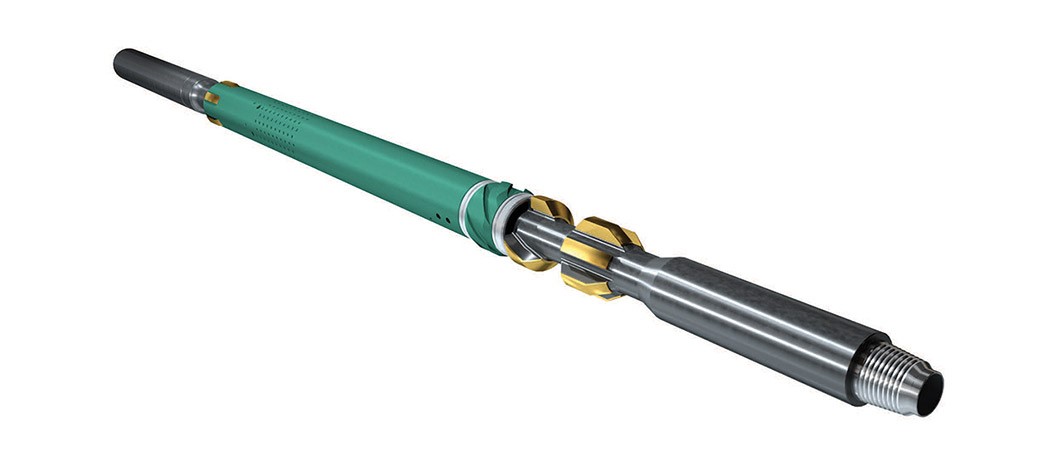

The PiRanha™ Junk XTractR™ is a robust wellbore clean-up tool and can be run individually or modularly as part of the ArmRdillo™ Wellbore Clean-Up System. The PiRanha™ Junk XTractR™ is designed to mill up and remove junk from the wellbore which could damage downhole equipment.

Features

- Robust Single Piece Mandrel

- Fluted free-rotating Centralizer Rings provide centralization and prevents casing wear

- Fixed bladed mill and junk scoop with tungsten carbide inserts and large single entry inlet port

- Large capacity junk basket

- Secondary boot basket capture debris in the annulus above the tool

- Can be quickly assembled redressed on location with simple hand tools

- No external bolts, clamps or fasteners that can come loose down hole

Benefits

Cost savings

- Field serviceable at the rig-site with basic hand tools

- Removes harmful junk preventing premature failures

Integrity

- Available with high torque connections reducing the need for reduced strength crossovers

- Single piece mandrel with no internal connections for increased strength

Reducing Non-Productive Time

- A robust wellbore clean-up is proven to reduce nonproductive time during the completion of the well

- Reduces failure of completion equipment by debris which can interfere with valves, electronics and other hardware

Applications

- Pre-completion wellbore clean-up operations where high levels of junk is expected

- Milling or heavy workover operations to remove junk and debris

- Cement drillout and accessory milling

Operational

- The PiRanha™ Junk XTRactR™ can be run as part of junk milling assembly or part of the pre-completion wellbore cleanup where high levels of junk is expected

- The PiRanha™ Junk XTRactR™ can be placed above a MunchRdillo™ Scraper Milling Tool and MAGStar4™ HD Casing magnet

- Whilst running in hole fluid enters the large single entry port or bypasses around the outside of the tool

- The fixed blade carbide mill breaks up any junk and the junk scoop introduces the junk into the junk barrel when rotating the workstring

- Junk circulated past the outside of the tool can be caught in the boot basket located at the top end of the junk barrel

- The drill string can be rotated and reciprocated without fear of damage or wear of the casing, drill pipe or of the PiRahnaTM Junk XTractRTM

- When pulling out of hole, the junk barrel boot basket captures additional debris from the wellbore

- The PiRanha™ Junk XTRactR™ can be quickly emptied at surface to inspect contents and can be redeployed quickly if necessary