How to drill a 40” conductor string using a crt tool?

There are two main challenges you face when you get carried away by the thought of drilling a conductor string: There are no bits big enough, and there are no CRTs that can handle bigger ODs than 26”. We managed to work around these limitations on the Maersk Resolute, operating on South Arne, getting the conductor to TD with a retrievable BHA. This is how we did it.

Problem

The biggest bits around are 36, so you need an underreamer on top of it, to get the wellbore wide enough for the 40” casing. For that you need a complex BHA, so drilling through with the next planned BHA is not an option. You have to find a retrievable solution. The BHA needs pressure and circulation to kick in. That is not obtainable from the top drive when the casing OD is this big. You would need a CRT to get sufficient pressure and circulation. The problem is that the CRT tools can only run on casing sizes up to 26”, so you are kind of chasing your own tail.

Solution

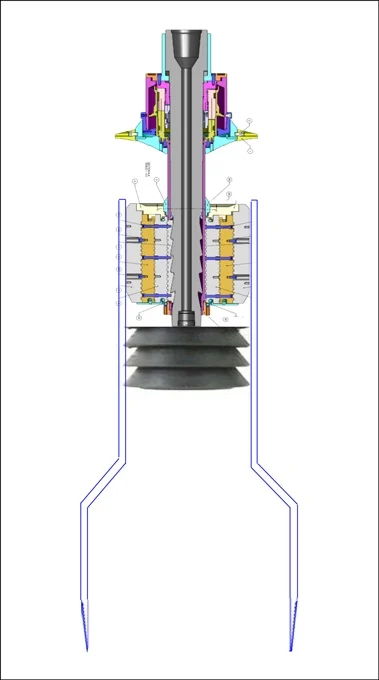

We assembled a BHA with underreamer and motor. The underreamer has a 17” body that extends to 45” hole size. At TD its arms retract, thus making it possible to POOH. That gave us a sufficient well size and a BHA that was retrievable.

But we still needed sufficient circulation and pressure, so there were challenges at the other end of the string. We designed a 13-3/8” to 40” swage interfacing the conductor OD with the largest OD a CRT is capable of running, ensuring circulation, pressure and rotation from one tool.

> Read also: Top drive casing running – why would you look for anything else?

Ground breaking

Conductor drilling (I prefer to use the term since Casing drilling is not possible with a casing of this size) is possible despite the obvious limitations associated with such an operation. We learned a lot from this project, and I will not hesitate to say that this is a method with a lot of potential both for the service providers and for the clients. There is a lot of excitement and motivation in doing something that has never been done before. Given the nature of our trade, that eagerness has to be somewhat stalled to maintain a secure and quality checked process. We took our time, using more than one year on a test rig. Being successful is about having a clear vision and controlling the surroundings.

Topics: Casing drilling

By: Leo Schneider

Leo is Operations Manager Casing & Rental Services at OWS.