Running casing in stands on a dual derrick rig

When being blessed with two derricks on your rig, you should take the full advantage of the extra opportunities this introduces. Running casing in stands is an obvious way to save valuable production time, and in this article I will show you why I consider it a crime not to seize the opportunity to save plenty of bucks.

The concept

Running casing in stands is simply put a pre-connection of casing tubulars prior to running the tubular in the hole. By connecting three joints together and racking them in the setback you reduce the time spent making up connections on critical line by 2 thirds. In order to do this in the most efficient manner, there are a few prerequisites:

- A dual derrick rig

- Casing filling tool

- Casing racking capability

The misconceptions

Why is it still a marginal method despite the obvious benefits and the already extra investments made? Well, the scepticism related to the solidity of the tubes has been a common objection , and has often been a showstopper. But the experiences are uniform and show that the pipe and connections are perfectly able to handle the stacking without being damaged. Most manufacturers will confirm this.

The disadvantages

To make an omelette you’ll have to break some eggs. Running casing in stands can sometimes require a larger casing crew. Especially on longer casing strings where you may risk filling the setback area before you have racked the required length of pipe. Since the stands are three times longer, it will require three times as much mud to fill up, and without a filling tool or autofilling casingshoe you will spend a lot of time standing still filling the casing.

The numbers

Now, let’s talk business and see what the potential economical outcome might be. The method might be used from 1500 to 4500 meters, but let’s go for 3000 in this example. In conventional casing you probably manage to run 12 joints/hour . You’ll need 250 joints for this casing string, so the total time is approximately 20 hours.

Running the same string in stands would in theory take about 7,5 hours. In real life it would take close to 10 hours. Assuming a rig rate of $350K you would save about $145K.. On a single casing run.

World record?

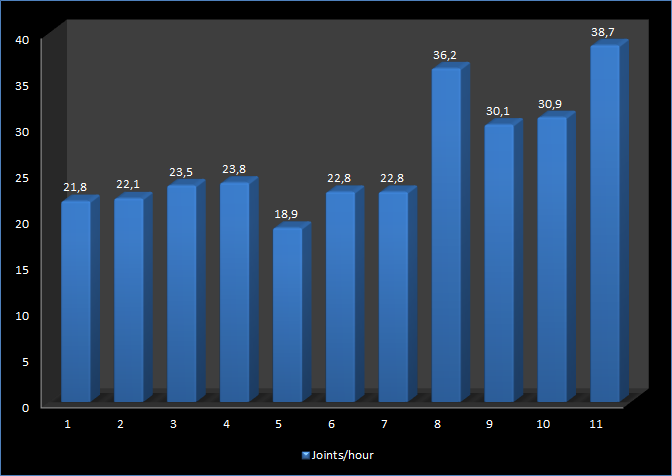

The following diagram shows the performance of a rig running 9 ⅝” casing in stands. At well number 8 you can see a steep increase due to implementation of a TDCRT.

> Se also: Top Drive Casing Running – Why would you look for anything else?

The conclusion

On a dual derrick rig, running casing in stands has a huge potential and should always be considered. As my example shows, the potential time savings are quite considerable. Even when calculating in the extra costs, running casing in stands should be profitable both time wise and economically.

Topics: Casing Running

By: Cato Gjesdal

Cato Gjesdal has 10 years’ experience from the oil & gas industry. As Sales & Project Engineer in Odfjell Well Services, he works with clients optimizing and improving tubular running operation such as casing running, P&A, completions and well testing.