The heaviest casing string ever run in Romania

Both equipment and competence were put to the ultimate test when Odfjell Well Services faced their heaviest casing string in Romania so far. Petrom – OMV subcontracted Rig Saipem 5870 was going to set 13 5/8” 14” Casing (535 Tones / 3801m) in the Baicoi field in Romania.

The first commercial oil well in Romania was drilled as far back as 1857, and the reservoirs in the Baicoi area was discovered in the beginning of the 20th century. In 1857 Romania set a world record of being the first country in the world to register an oil production of 275 Tones in the international statistics.

Petrom has been the number one operator in Romania for decades and was aware of the challenging formations of the area, thus being really well prepared when they started this job.

Outer limits

The drilling of this HPHT well started in January 2018, and the importance of the project was emphasized by the fact that the client had never handled such a big casing before. Make-up torques were expected to reach 60.000+ lbf.t. for the 14″ string and running 24 1/2″ surface casing was new to everyone.

By mobilizing equipment from all over Europe, Odfjell Well Services was able to equip the 650-ton rig to its outer limits. In fact, the tubular running equipment headroom exceeded the rigs headroom.

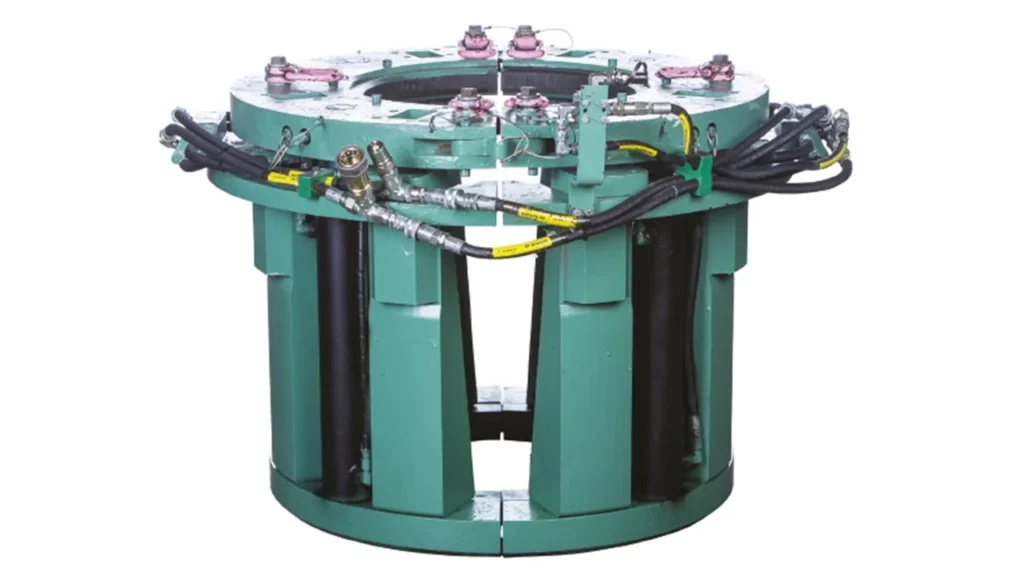

Big tubular running equipment

We used mainly remote operated equipment as we looked to reduce manual operation and keep people out of the red zone. When we made this configuration, we had a personal security mindset.

- CRTI (690 ton)

- Power Tong, 14” x 100K lbf.ft rating c/w 15”

- Vermillion Flush Mounted Spider (1000 ton) 13” – 14” range

- 13 5/8” Air Operated Spider / Elevator (500 ton), backup

- 14” Air Operated Spider / Elevator (750 ton), backup

Tough equipment for tough challenges

We made our way through the Baicoi formations with a couple of challenges that put our equipment and skills to the test:

- From 3791m down to TD (3801m) we ran into tight hole conditions. With the TDCRTi we had the ability to reciprocate and circulate the casing – a feature that showed decisive in getting through the difficult section.

- The Top Drive System encountered difficulties in providing sufficient torque for reaming the casing string. On one occasion towards the end of the section, the drawworks brake was challenged to hold the total string weight properly, and we had to let it cool down for one hour before we could proceed.

Casing landed safe at TD

The string was washed down to TD (1200-2000 LPM), reamed and filled at each joint using the CRTi.

Although big size casing runs have been executed multiple times throughout the industry, this was a first for us in Romania. The Petrom OMV site representatives and the Saipem crew contributed heavily to this success, with Odfjell proving the ability to provide tools for demanding operations.

The remote operated equipment and Odfjell’s zero fault philosophy brought the heaviest casing string in Romania to TD without any incidents, NPT or personal injuries.

Topics: Casing Running, Tubular handling

By: Alexandru Gomoescu

Alexandru has been in the oil and gas industry for ten years providing drilling related services such as casing drilling, tubular running and drilling equipment rental. He is now Regional Manager (CESEE) at Odfjell Well Services.