Unlocking more sustainable wellbore cleaning methods

According to the IEA, oil and gas operations are currently responsible for around 15% of global energy-related emissions, amounting to roughly 5.1 billion tonnes of greenhouse gas emissions[1]. And as the industry continues to evolve, operators face a significant challenge in balancing how best to deliver safe, secure and efficient results while reducing emissions and minimizing environmental impact.

This is why effective wellbore cleaning is critical. Operators need to prioritize avoiding damage to equipment during completion, delays in production, minimizing operational costs and significant non-productive time.

Because every additional hour spent on wellbore cleaning results in higher fuel consumption and carbon dioxide emissions, Odfjell Technology focuses on delivering smarter wellbore cleaning solutions that cut cleaning time – lowering both costs and emissions.

Smarter cleaning, stronger sustainability

Every well is unique, and efficiency depends on adapting solutions to local challenges. Our ability to deliver integrated, fit-for-purpose wellbore clean-up packages or individual tools ensures operators get the right balance of reliability, efficiency and sustainability.

This focus is particularly important in Norway, where the petroleum sector contributes nearly one quarter of the country’s total greenhouse gas emissions. With energy efficiency now a key priority for operators, cleaner and more effective solutions are in high demand[2].

A Norwegian customer recently demonstrated this in practice, when a problematic blowout preventor filled with stubborn debris was successfully cleared using an Odfjell Technology Hydraflow Advanced Wellbore Cleaning Tool. By combining offset jetting nozzles and an optimized flow path, the operation saved the client 33 hours of rig time and USD $773,000. The approach was so effective that it was replicated across nine further wells, multiplying both the efficiency gained and emissions reductions.

Proven efficiency, measurable results

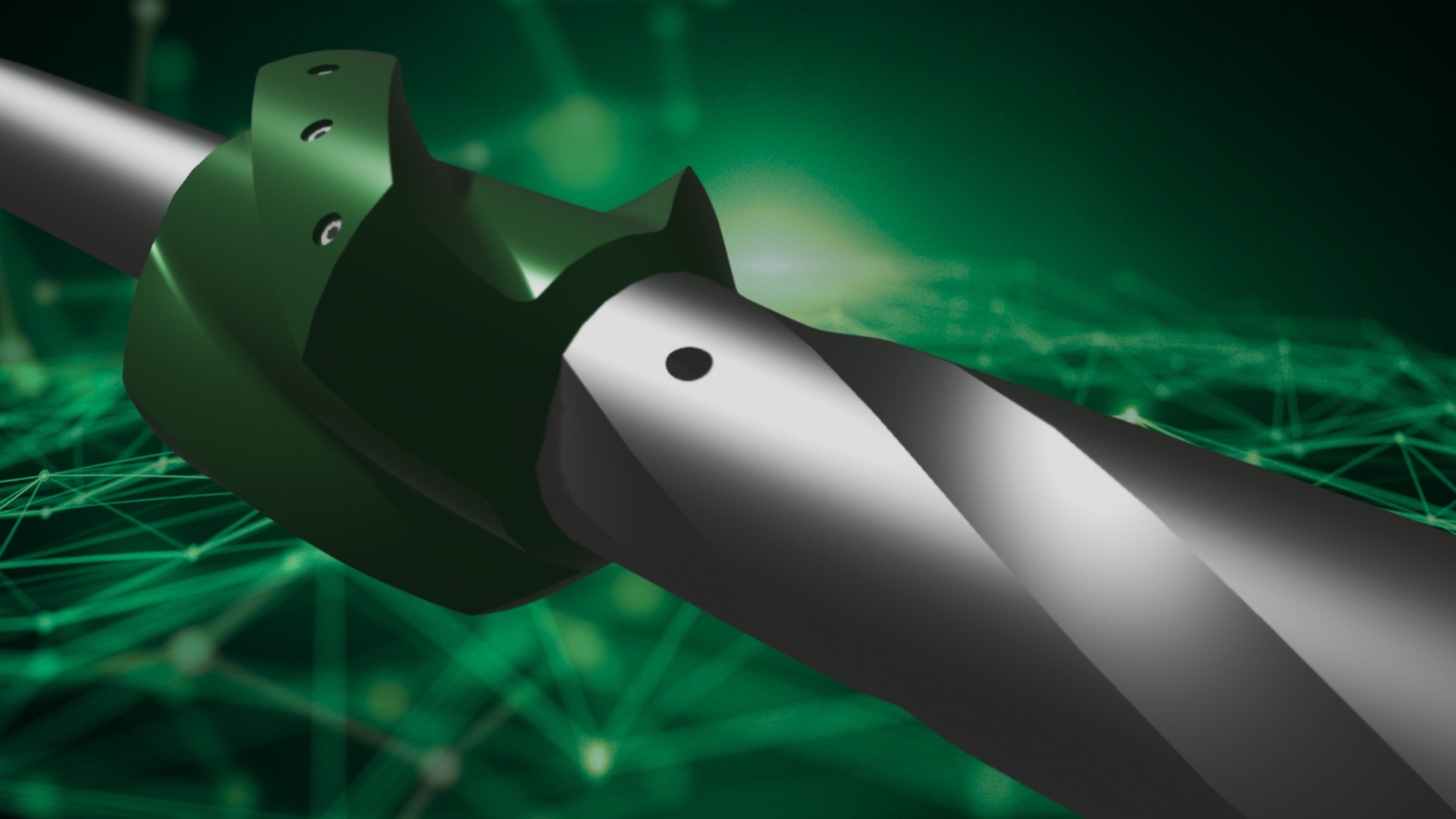

With more than five decades of experience in well services, our innovative technologies and products, such as the RizeRdillo Riser Combi Tool and the DrillRdillo Drilling Scraper deliver reliable results to ensure the safe and efficient removal of debris and contaminants from the wellbore.

Our flexibility was critical in the Asia-Pacific region, where a highly deviated deep well with multiple depleted zones required both drilling and scraping. By deploying the DrillRdillo in a single run, the operation saved 34 hours of rig time and USD $375,000, demonstrating how the right tools can turn a complex clean-up into a streamlined success.

And in the UK, a client needed a one-trip drill-out of a reservoir section while also scraping multiple packer setting depths – a complex operation in challenging well geometry. Our DrillRdillo tool, supported by in-house software, saved 14 hours of rig time and GBP £131,000, where standard industry solutions would not have worked.

Experience you can trust

With operations across the world, operating in over 30 countries, we are proud to combine global reach with deep technical expertise. As the industry navigates the energy transition, our evolving product line is designed to help operators meet today’s economic and environmental demands. By reducing non-productive time, cutting emissions and unlocking smarter ways of working, Odfjell Technology is driving a more efficient and sustainable future for wellbore cleaning.

To learn more about Odfjell Technology’s portfolio of wellbore cleaning solutions, click here.

[1] https://www.iea.org/reports/emissions-from-oil-and-gas-operations-in-net-zero-transitions

[2] https://www.norskpetroleum.no/en/environment-and-technology/emissions-to-air/