Why improved casing running requires an experienced casing crew

The rotation system on a rig means that a drilling crew may go months or even longer without even being present when the casing are being made up and set. That makes up for using a specialized crew to handle the casing running.

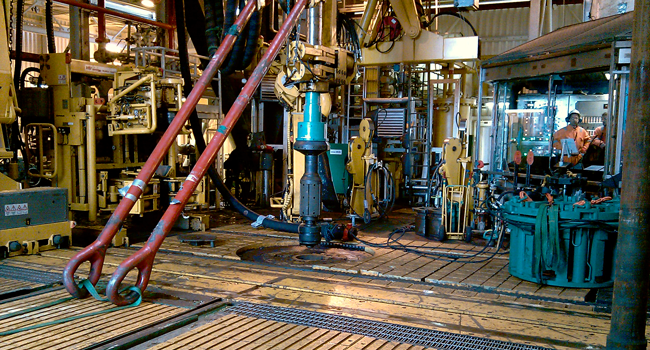

Equipment is different

Just think about it: Why is casing equipment not an integral part of the rig? The project at hand dictates the casing process in such a manner that the equipment will vary. For instance, the formation will dictate what kind of sealing you need, and pipes are suited for the environment it will be used. This also influences the casing size, which then decides the TRS equipment required.

The market for casing equipment rentals has motivated suppliers to develop their own equipment, which they of course are very comfortable operating. In addition, the advanced software running this equipment needs particular know-how, and who would be more suited to operate it than the ones who developed it?

Pipes are different

The power tight connections needed in casing are more fragile than the connections of drill pipe, and manufacturers specifications vary greatly. A TRS-expert need to be up to date on this and regularly attend manufacturers training classes to be able to treat their threads correctly. This expertise is needed on site to overlook the connections, and to ensure the correct make-up is applied.

The challenges are different

We all look good when things are going well and the formation seem to be exactly as the geologist told us. But what happens when an unpredicted hazard occurs? How fast and accurate is the crew able to deal with equipment break down? Or in an event of stuck: How will an inexperienced hand help out the situation operating the casing equipment, if its primary job is drilling?

The skills required are different

To be on top of the casing game you need to run casing on a regular basis. As a member of the drilling crew you have lots of other responsibilities and because of the rotation system, you’re probably not on site most times when the casing is run.

The need for being up to date on specifications and documentation on the equipment involved is also a key point, as is the interpretation of torque turn computer graphs; if you are not used to it, it’s hard to know what to look for.

The organization is different

In many projects POB is an issue. A drill crew is tailored to suit the demands without being too many. If they are assigned to running casing, someone else have to fill in for them. This spiral is bad for efficiency and you end up having people assigned to tasks they are not primarily hired for.

A dedicated casing crew is made up of motivated specialist focusing on just that. They are carefully briefed before they appear on site, something that makes the communication with the rig manager run smoothly, and ensures an improved casing running.

You need different people

The reasons for making this a trade within the trade are obvious: Planning, organization, equipment and know-how differs from the other down-hole activities in such a manner that special focus, training and operation are necessary to obtain the quality and safety required to succeed. The casing is not something you carry out while being preoccupied with other parts of the project. Do not start just to check out how far you can go on your own. NPT will just rocket away.

An experienced casing-crew is required in all projects, and the importance of them being just that; trs experts, cannot be underestimated.

Topics: Casing Running

By: Svein Krosli

Svein has been with OWS for 15 years as TRS technician, technical supervisor and instructor. He is now Global Product Line Manager, Tubular Running Services.