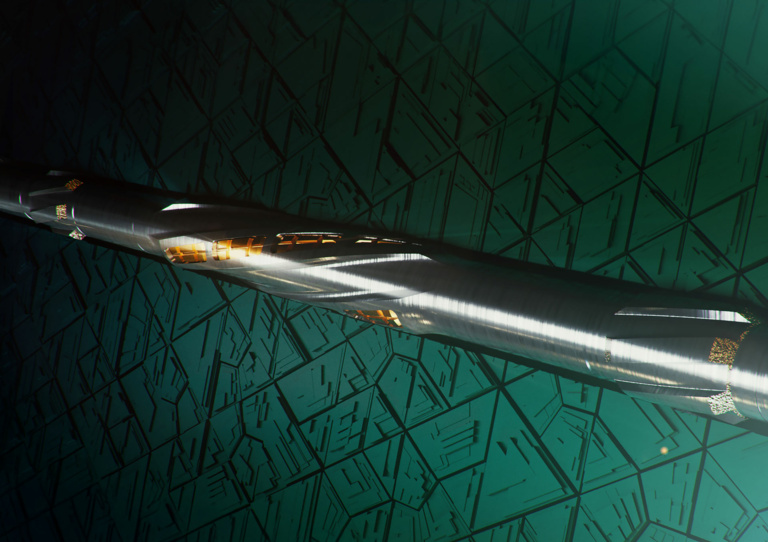

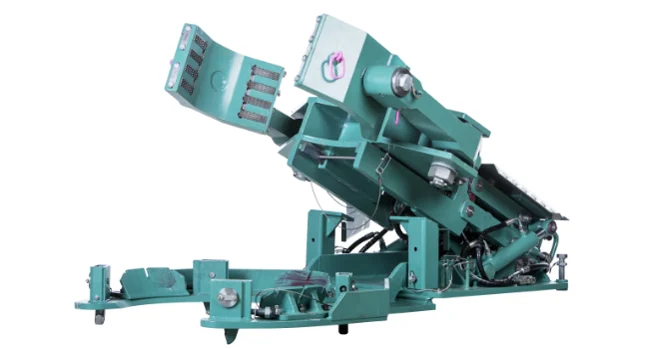

Built on heritage,

innovating for the future

Combining 50 years of industry experience with the technology of tomorrow, we develop solutions for the changing energy market.

An ongoing commitment

Our sustainability approach

Odfjell Technology’s commitment to sustainability is based on high ethical standards, integrity, respect for people and care for the environment.

- Global

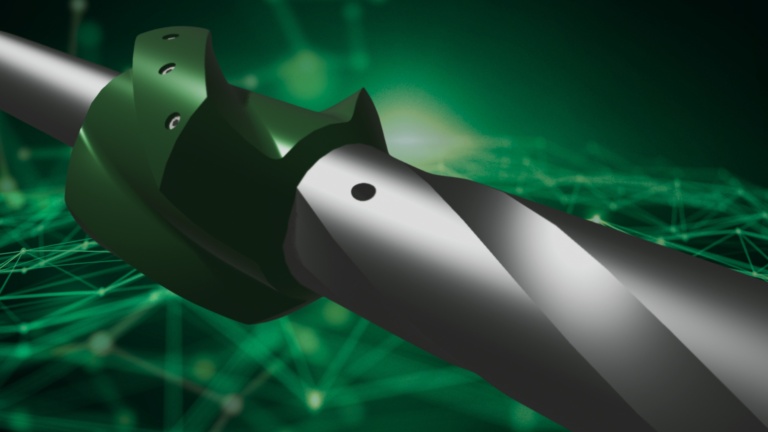

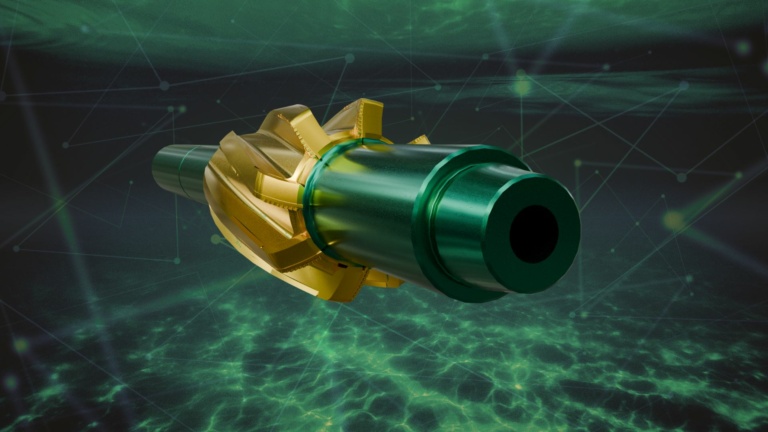

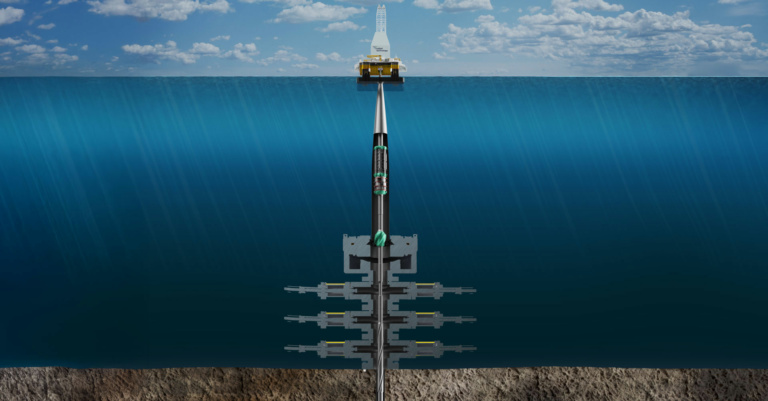

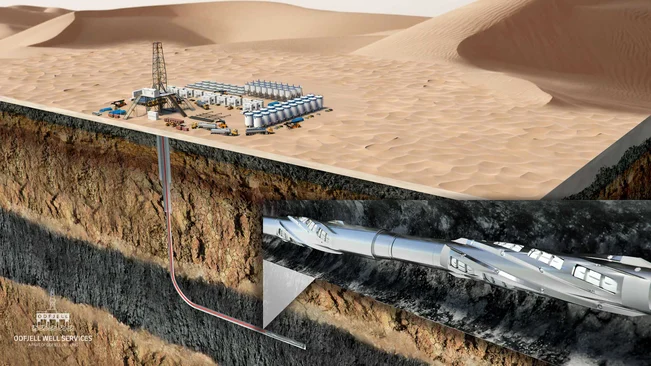

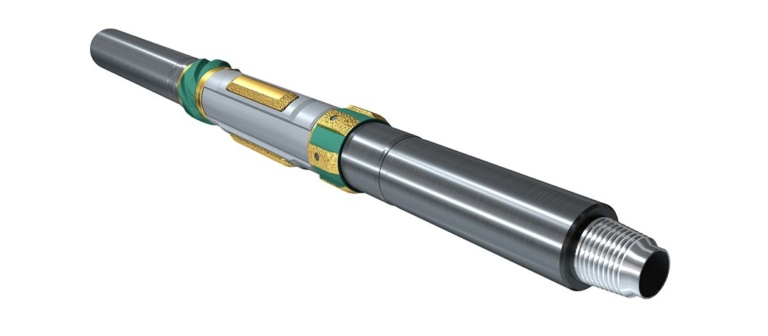

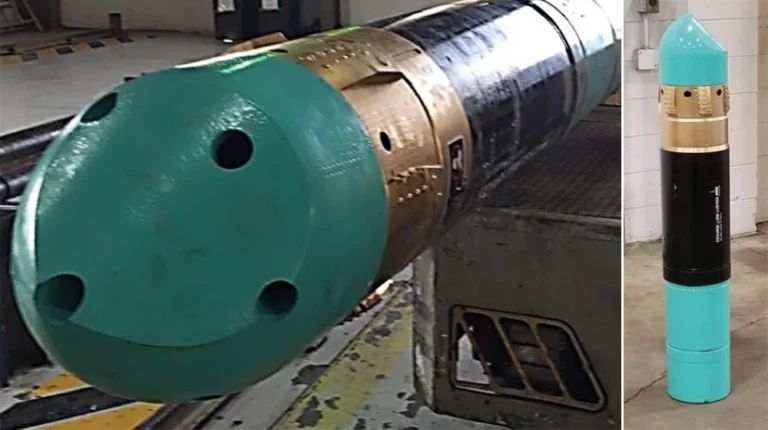

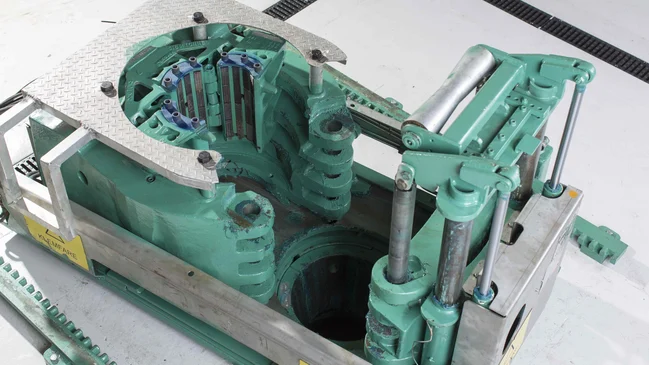

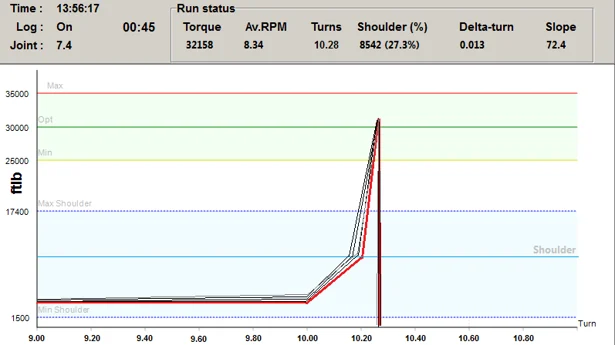

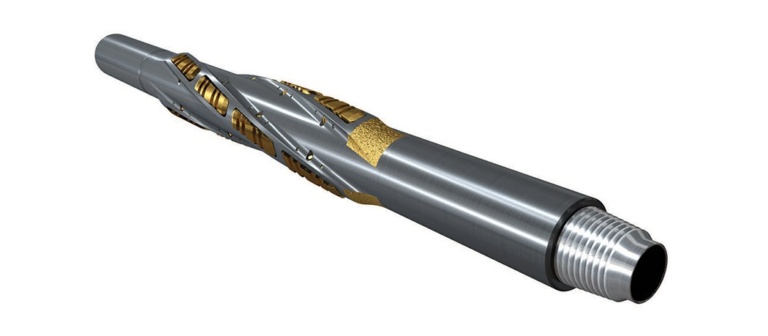

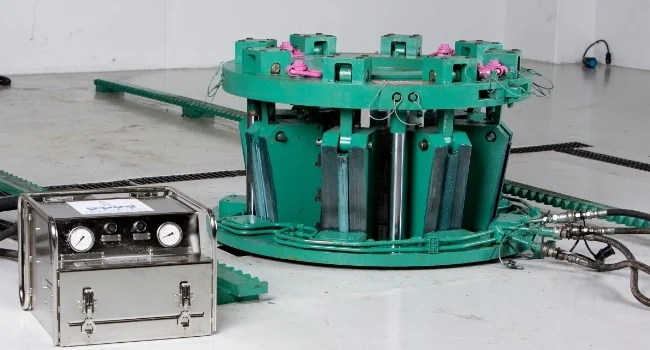

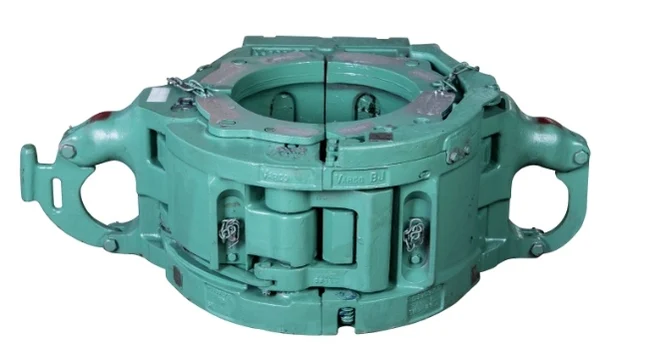

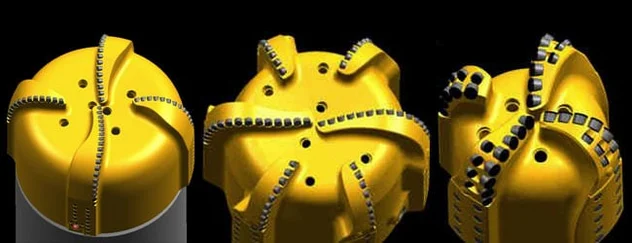

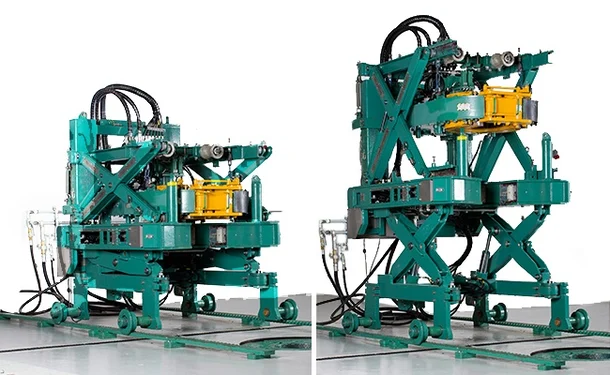

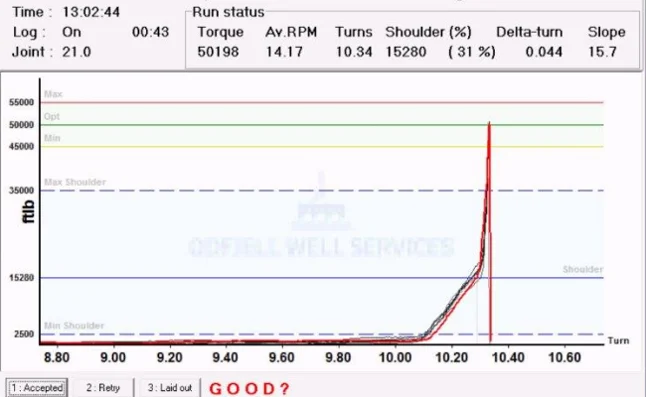

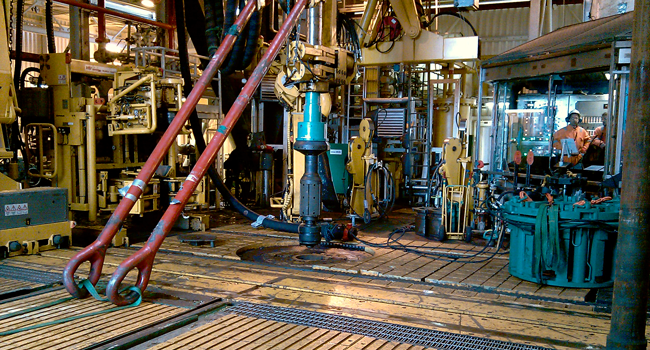

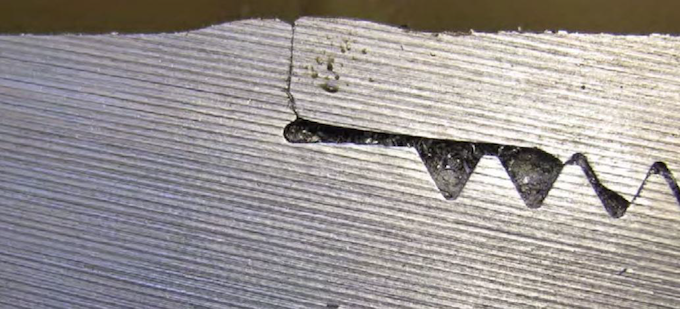

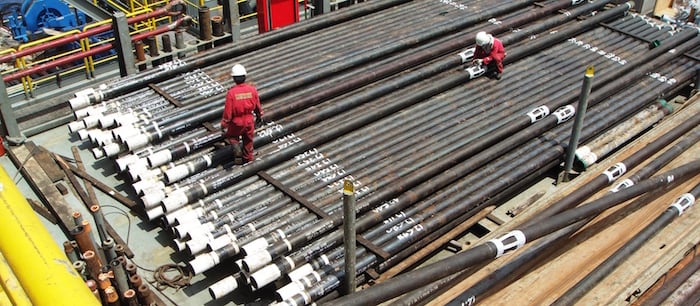

- Well Services

- Engineering

- Drilling Operations

QHSE – Competence and capacity, the key to safety

Quality

We are committed to deliver high quality, innovative services and products to our clients in accordance with internal and external expectations.

Health

Healthy workplaces are safe, inspiring and promote well-being. We invest to ensure that our employees experience the best, feel their best and achieve the best.

Safety & Security

Safety comes first, always. We manage and reduce risk through rigorous requirements and a culture founded on the protection of people and assets. We protect our business from potential security threats, including cyber security threats.

Environment

We are focused on safeguarding the environment and minimising any potentially negative impacts from our operations. Our aim is to be an industry role model for first class environmental performance.

Why choose Odfjell Technology

Employee stories

I am constantly learning something new, and feel lucky to work with so many different, talented people.

Amanda Karina Bakhtiari, Assistant Driller, Drilling Operations

Ever since I started in Odfjell Technology, I have been challenged, learned a lot and become more independent. I have received training and been well taken care of, yet I regularly have the chance to show what I can do and become the best version of myself.